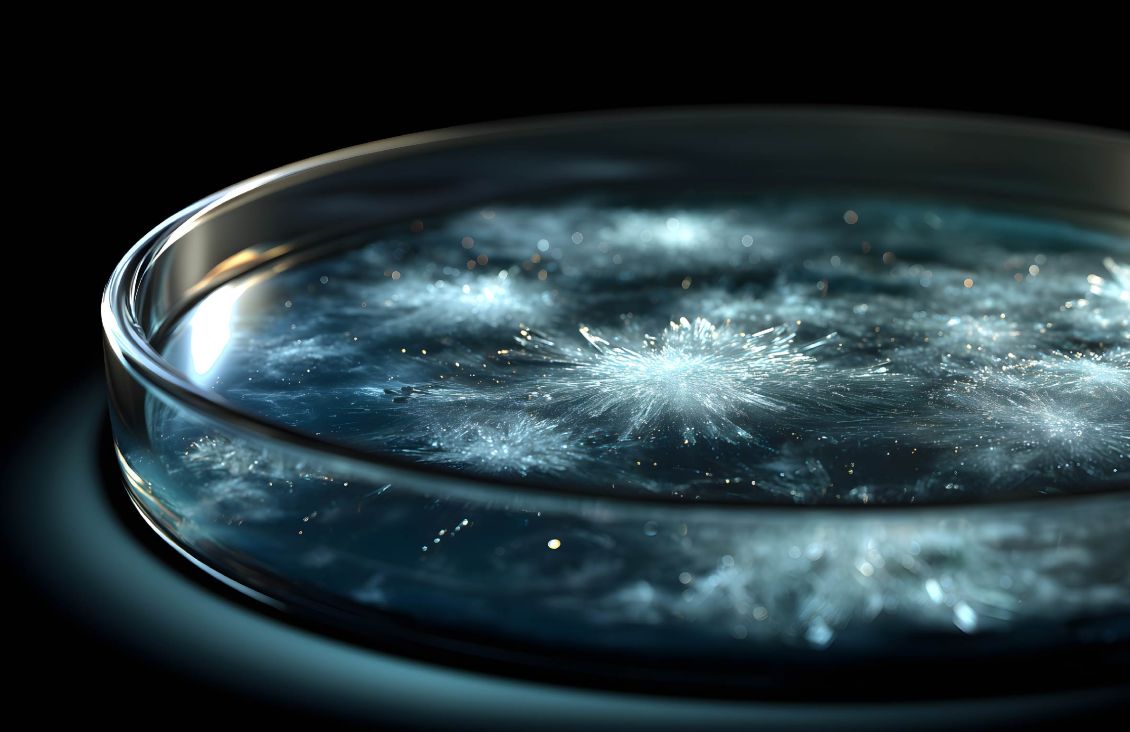

Crystallization in epoxy resin can often catch users off guard. You open a container expecting a clear, fluid material—only to find something cloudy, thickened, or even fully solid. Is it a problem? Surprisingly, no. In fact, epoxy resin crystallization is a natural, reversible process that’s more about science than spoilage.

In this blog, we’ll walk you through what crystallization is, why it happens, how to recognize it, and most importantly, how to handle it when it occurs.

What Is Epoxy Resin Crystallization?

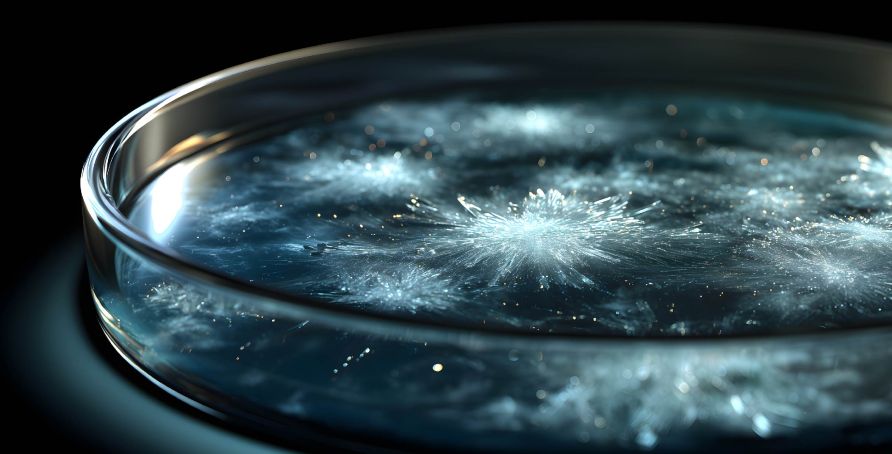

Crystallization is a phase change—the transition of epoxy resin from a liquid to a more solid, crystal-like state. Think of it like water turning into ice. And just like ice melts back into water, crystallized epoxy resin can be returned to its original liquid form with the right treatment.

The key takeaway: crystallization doesn’t damage the resin or alter its original properties.

Signs Your Epoxy Resin Has Crystallized

Crystallization can look different depending on its stage. Here’s what to watch for:

- Cloudiness or haziness in what’s normally a clear resin

- Floating crystals or sediment forming at the bottom

- A milky white appearance

- Thickened, grainy texture

- Fully solidified material in extreme cases

Often, crystallization begins at the bottom or sides of the container and gradually spreads. If left undisturbed, it may solidify completely—but even then, it’s not ruined.

Why Does Crystallization Happen?

Epoxy resins are what chemists call super-cooled liquids—they stay liquid below their freezing point until something (like a seed crystal or a temperature drop) triggers crystallization.

Here are some common causes:

✅ Temperature Fluctuations

Cold conditions or thermal cycling (e.g., between day and night) can encourage crystals to form and grow.

✅ Resin Purity

High-purity resins have a higher tendency to crystallize due to a narrower molecular weight distribution.

✅ Low Viscosity

Lower viscosity allows molecules to move more freely and orient into crystalline structures faster.

✅ Fillers & Additives

Some solid additives like calcium carbonate, silica, or even microscopic scratches on the container walls can act as “seed sites” for crystal growth.

How to Reverse Crystallization

If your epoxy resin has crystallized, simply follow these steps:

- Gently heat the container to 40–50°C (104–122°F) for a few hours.

A water bath or heat oven works best—just ensure even, controlled heating. - Inspect thoroughly to ensure all crystals are melted.

Pay close attention to the container bottom, sidewalls, and around the cap. - Cool slowly to room temperature to prevent rapid reformation of crystals.

Pro Tips to Prevent Crystallization

While you can’t always prevent crystallization, a few smart practices can help:

- Store resins in a temperature-controlled environment

- Avoid extreme cold or rapid thermal cycling

- Clean the container neck and cap after each use (IPA or acetone works well)

- Keep pumps, valves, and spouts clean to avoid seed formation

- Monitor shipping and storage conditions, especially during colder months

Final Thoughts

Crystallization may look concerning, but it’s completely reversible and does not affect the performance of your epoxy resin. With a bit of knowledge and the right storage practices, you can handle it with ease and confidence.

Disclaimer: The information provided in this blog is for reference only. Always evaluate products in the context of your specific application. For full technical guidance, refer to product datasheets and SDS documents.

Get in touch

Need help identifying or reversing crystallization in your product?

Contact our technical service team at 978-667-3805 or

Email us at: