Worker safety & health safety aspects of E-Chem EPC overlay system versus PPC system

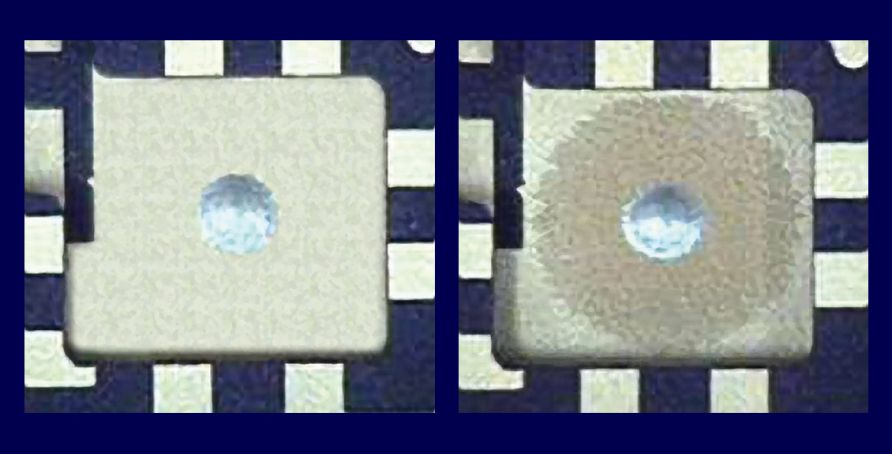

There are two primary accepted screeded polymer concrete systems for protecting bridge decks. The first method, used since the mid-1980s, is a polyester-styrene resin coating (PPC) system, similar in characteristics to a fiberglass resin. The second, newly engineered E-Chem method, is an epoxy polymer concrete (EPC) overlay system.

This newly engineered method is an all-in-one, 100% solids, solvent-free, moisture insensitive, high-performance, multi-purpose EPC overlay system. This EPC overlay system combines a low-modulus epoxy resin system with a blend of graded, clean, and dried aggregate to achieve the optimal set of characteristics for an EPC overlay system that is both an effective structural alternative and extremely safe to use. The EPC system is superior to the existing PPC systems with regards to worker safety throughout the application process, product volatility throughout the material staging and storage process, and overall environmental health, including cleanup and disposal. The E-Chem EPC overlay system offers a safer, better performing option to the historic PPC overlay products.

The E-Chem EPC overlay system components may be safely mixed in the field, using existing application equipment or infrastructure, as a two-component polymer with the appropriate aggregate material.

The historic PPC overlay components are hazardous, should require the use of respiratory and dermal protection, and must be mixed precisely in the field to avoid the potential for fires and explosion while in use and storage under environmental conditions (e.g. elevated temperature) routinely experienced during the staging and application process on a jobsite.

The E-Chem EPC overlay system components may be stored at ambient temperature, while historic PPC overlay products direct the user to store resins in closed containers at temperatures below 77ºF (25ºC), requiring temperature-controlled storage locations, which is not economically or spatially feasible on a standard jobsite.

The historic PPC overlay products caution the user to keep away from heat, flames, sparks, and ignition sources (e.g., sparking tools, welding, cutting, brazing, soldering, drilling, grinding, pilot lights, internal combustion engines), and direct sunlight, keep out of designated smoking areas, keep containers tightly closed, and use in well-ventilated spaces. The EChem EPC overlay system components are void of such cautions and offer the operational flexibility of varied acceptable storage and use parameters. For the E-Chem EPC overlay system, both Component A and Component B are only mildly corrosive, as compared to the historic PPC overlay system which is more corrosive.

When mixed, the EPC mixture is innocuous. EPC-Overlay Component A is a diglycidyl bisphenol resin and EPC-Overlay Component B is a phenol derived from a natural product. Both Component A and Component B are simple skin and eye irritants and do not cause severe skin burns or eye damage, like PPC overlay systems. The recommended personal protective equipment (PPE) need only include Level D, consisting of standard work gloves and traditional safety eyewear common to any construction site.

The EPC overlay system may be mixed by hand for small-scale applications or by using existing volumetric batching to mix in the field together with the specified aggregate material. When mixed the resulting E-Chem EPC overlay system product does not off gas, does not produce foul odor, and does not present any subsequent physical or chemical hazards to the worker. The E-Chem EPC overlay system components (Component A and Component B) are not flammable. No pretreatment of the deck is necessary to apply the E-Chem EPC overlay system, which increases worker safety and health, saves time during the application process, and provides a more economical alternative.

Application of the historic PPC systems require use of high molecular methyl methacrylate as a pretreatment to the deck surface. High molecular methyl methacrylate is considered hazardous by the 2012 OSHA Hazard Communication Standard (29 CFR 1910.1200). High Molecular Weight Methyl methacrylate is flammable with vapors forming explosive mixtures when mixed with air.

Safe handling of High Molecular Weight methyl methacrylate with the historic PPC system is imperative because the off-gassing vapors during the mixing process may travel to source of ignition resulting in a flash back and potential explosion. When exposed to elevated heat, high molecular weight methyl methacrylate containers have the potential to overheat, generate flammable vapors, and explode. Elevated heat is commonly experienced on the jobsite or in material storage warehouses. Industry leaders have acknowledged the historic PPC overlay system and its components as a flammable and potentially explosive product. Manufacturers have identified these hazardous conditions on warning labels and provide rigorous requirements for the storage, mixing, and application of the PPC overlay system products.

The historic PPC overlay system requires the use of prescriptive respiratory and chemical resistant PPE for worker safety during mixing and application procedures. Robust chemicalresistant safety gloves, eye protection, and other protective hazmat clothing (exceeding PPE Level D) must be worn while working with PPC overlay system components. An advanced respirator with organic vapor cartridges (PPE Level C) or supplied air (PPE Level B) is necessary when exposures have the potential to reach the Permissible Exposure Limit (regulatory values set by OSHA) while working with PPC Binder Resin in the historic PPC overlay system. Threshold Limit Values, from the American Conference of Governmental Industrial Hygienists, may provide a more conservative approach to maximum average airborne concentrations of certain contaminants an adult worker can routinely encounter over a working lifetime without experiencing significant adverse health effects.

If the historic PPC overlay system application includes the Cobalt promoter supplied separately from methacrylate-based resins, extra care must be taken to avoid contact between Cobalt promoter and peroxide catalyst components because a violent exothermic reaction will occur. Manufacturers provide product warning labels with guidance on use of spark-proof tools and explosionproof electrical equipment (e.g. ventilation, lighting, material handling equipment) when handling and storing the historic PPC overlay system products. Additional guidance from manufacturers suggests bonding and grounding practices be used to reduce the likelihood of static electricity igniting flammable vapor evolutions during the material transfer process. The historic PPC overlay system three-component pretreatment has the potential to become explosive when mixed in the wrong proportions. Because the historic PPC system components are a flammable and potentially an explosive product, specific precautions must be taken with respect to the mixing, storage, and application of the older, PPC system components.

Manufacturers of the historic PPC system components are aware of the primary routes of exposure to workers (i.e., including inhalation, absorption, ingestion), and provide warning labels to avoid inhalation, contact with eyes, skin, and mucous membranes along with general precautions for increased hygiene. The EChem EPC overlay system does not contain cobalt or methacrylate and is not classified as a flammable or explosive. The styrene resins present in the historic PPC system components off gas hazardous Volatile Organic Compounds (VOCs).

Off gassing VOCs are flammable and produce nuisance odors to workers and surrounding communities. Exposure to VOCs can cause difficulty breathing, irritate the nose, eyes, and soft tissues, and cause damage to the central nervous system and other organs. The EChem EPC overlay system components and finished product do not contain VOCs and do not off gas VOCs. With the E-Chem EPC overlay system, contractors do not have to wear organic vapor respirators (PPE Level C) throughout the application process and there are no chemical nuisance odors in the application area. Furthermore, the historic PPC systems contain styrene, which identified as a Hazardous Air Pollutant by the U.S. Environmental Protection Agency (EPA) and is listed on the California, Proposition 65 as a Highly Suspected Human Carcinogen. Hazardous air pollutants (HAPs, also known as toxic air pollutants or air toxics), are pollutants known or suspected to cause cancer or other serious health effects, such as reproductive effects or birth defects, or adverse environmental effects.

Exposures to styrene can adversely affect the central nervous system vision changes, lethargy, slow reaction time, difficulties concentrating, vertigo, and other symptoms of intoxication. The E-Chem EPC overlay system product and components do not contain styrene and are not identified as carcinogenic. The application of the historic PPC system is an extremely hazardous exercise because of the component flammability, explosion potential, high VOC concentration, and carcinogenicity. The application of the EChem EPC overlay system is a nonhazardous exercise with no flammability potential, no explosion concerns, no VOCs, and no carcinogens.

Worker safety considerations for use of the E-Chem EPC overlay system includes use of standard, job site PPE with gloves and eye wear (PPE Level D). Worker safety for the application of the historic PPC system includes enhanced respiratory protection consistent with PPE Level C or PPE Level B (organic vapor or supplied air). With the potential for fires and explosion from VOCs and exothermic reactions, the historic PPC system components require use of dry chemical, carbon dioxide (CO2 ), or foam as extinguishing media for firefighting measures. Use of a normal/standard water spray/jet for firefighting is not suitable for the historic PPC system. The E-Chem EPC overlay system does not have the potential for fires and explosion. Depending on quantities, additional security precautions should be considered, along with applicability of supplemental National Fire Protection Agency (NFPA) and/or Occupational Safety and Health Administration (OSHA) guidance, notifications, or other requirements.

Because components of the historic PPC system are hazardous, the collection and treatment of spills is necessary. The E-Chem EPC overlay system components and product are not hazardous and do not require special disposal methods. The cleanup of the newer EPC system application is with simple water-based products or pressure washer. The clean-up of the historic PPC system application may require more hazardous products. The OSHA General Duty Clause requires employers provide a work environment “free from recognized hazards that are causing or are likely to cause death or serious physical harm.” The National Institute of Occupational Safety and Health (NIOSH) reenforces this position by stating “controlling exposures to hazards in the workplace is vital to protecting workers.”

NIOSH also introduces the Hierarchy of Controls, with five (5) levels of action to reduce or remove hazards – elimination, substitution, engineering controls, administrative controls, and PPE (in preferential order). The use of the newer EChem EPC overlay system in place of the historic PPC is an example of how substitution can be used to increase worker safety, by use of a product with fewer application hazards and environmental contamination concerns and by eliminating the need to put the worker in restrictive and expensive PPE. The use of the new EPC system over the historic PPC system significantly reduces the financial risks of the product application process. Many commonly accepted industry practices using more hazardous components have been replaced with newer technology products that are not significantly hazardous. Performance of the new EPC system is better than the historic PPC system for ease of use, comparable cure times, and longevity in the field.

Authors

Kelsey L. Forde

CIH CSP CHMM Owner, Principal Environment, Health, & Safety Professional, Parvati Consulting LLC Albuquerque, New Mexico, United States Timothy S. Stirrup CSP CHMM REM Principal Environment, Health & Safety Professional, Parvati Consulting LLC Albuquerque, New Mexico, United States

Timothy S. Stirrup

CSP CHMM REM Principal Environment, Health & Safety Professional, Parvati Consulting LLC Albuquerque, New Mexico, United States

This comprehensive analysis highlights how the EPC Overlay System offers a safer, more efficient alternative to traditional PPC systems. With its innovative, non-hazardous design, the EPC system eliminates VOCs, flammability risks, and complex PPE requirements—all while enhancing performance and environmental sustainability.

Download EPC vs PPC whitepaper