When choosing an epoxy adhesive for your application, rheology—how the material flows—can make or break your process. Two key terms that describe this behavior are viscosity and thixotropic index (TI).

In this post, we’ll explain what these terms mean, why they matter, and how they can guide you in selecting the right epoxy for your application and dispensing method.

What Is Viscosity?

Viscosity is a measure of a fluid’s resistance to flow. It’s typically measured in centipoise (cPs)—with water having a viscosity of 1 cPs. The higher the cPs, the thicker or more resistant the material is to flow.

Here are some examples of common materials and their viscosities at room temperature (70°F):

| Material | Viscosity (cPs) |

| Water | 1 |

| Milk | 3 |

| SAE 10 Motor Oil | 85–140 |

| Karo Syrup | 5,000 |

| Honey | 10,000 |

| Chocolate | 25,000 |

| Ketchup | 50,000 |

| Mustard | 70,000 |

| Sour Cream | 100,000 |

| Peanut Butter | 250,000 |

Pro Tip: You can reduce the viscosity of an epoxy by increasing the temperature, making it easier to dispense. However, be cautious—higher temperatures can accelerate cure time and shorten pot life.

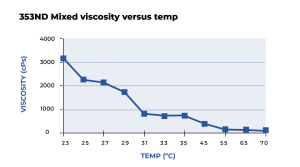

Case Study: EPO-TEK® 353ND

The chart below demonstrates how EPO-TEK® 353ND behaves when heated. Its viscosity drops rapidly with even a small increase in temperature, then levels off:

| Temp (°C) | Viscosity (cPs) |

| 23 | 3153 |

| 25 | 2252 |

| 27 | 2147 |

| 29 | 1728 |

| 31 | 785 |

| 33–35 | 737 |

| 45 | 409 |

| 55 | 163 |

| 65 | 143 |

| 70 | 102 |

This makes temperature control a useful strategy if a product is ideal for an application but starts out slightly too thick.

What Is Thixotropic Index (TI)?

Thixotropic Index (TI) measures how much a material’s viscosity changes under stress—like stirring, dispensing, or brushing. It’s calculated as the ratio of viscosity measured at two different shear rates, typically differing by a factor of 10.

A high TI indicates a material that maintains its shape when undisturbed but becomes more fluid when shear is applied.

A perfect real-world example? Mayonnaise. It stays put on your sandwich until you spread it.

For epoxy users, this is especially important in dispensing, screen printing, or applying epoxies to vertical surfaces.

Why These Properties Matter

When choosing an epoxy, consider:

- Viscosity: Will it flow easily into your mold, gap, or application area?

- TI: Will it stay where you place it or run/settle before curing?

Together, these properties affect:

- Dispensing performance

- Flow and leveling

- Precision in applications

- Final bond strength and coverage

Final Thoughts

Viscosity and thixotropic index may seem like technical jargon, but they’re essential to understanding how an epoxy will perform in the real world. By selecting materials with the right rheological properties, you ensure easier processing, more accurate application, and better results.

Need help choosing an epoxy with the right flow characteristics for your needs?

Contact our experts at techserv@epotek.com