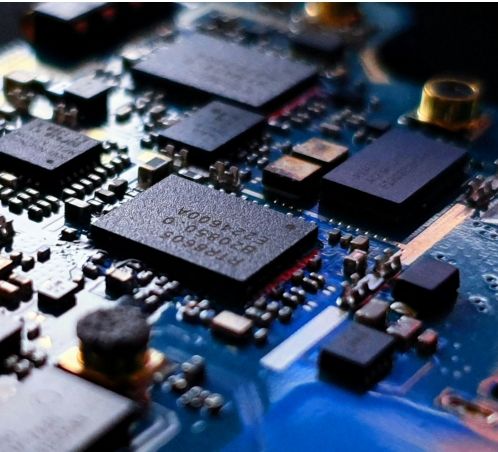

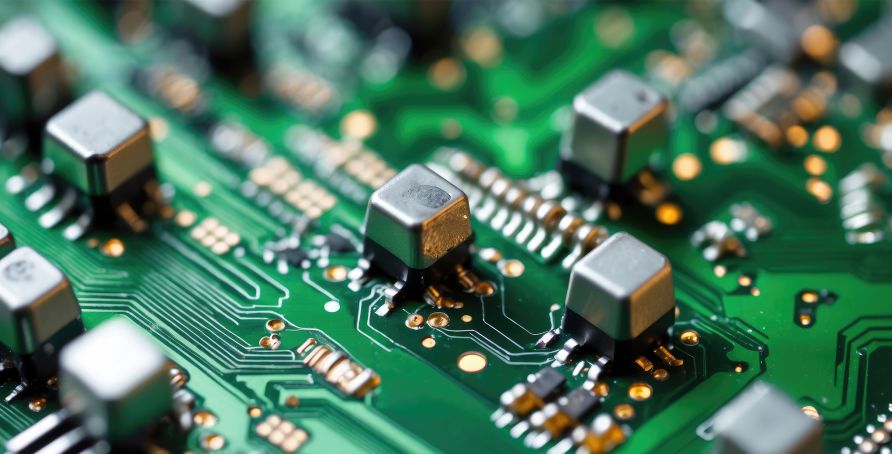

When it comes to adhesive bonding, choosing the right epoxy is only half the equation. The other—equally important—part is surface preparation. Without it, even the best adhesive can fail.

In this blog, we break down why surface prep matters, the difference between adhesive and cohesive failure, and how to optimize your bonding results across a range of materials.

Why Surface Preparation Is So Important

Proper surface preparation is essential to achieving strong, reliable bonds. Whether you’re bonding metals, plastics, ceramics, or glass, the adhesive-substrate interface must be clean, chemically receptive, and physically prepared to accept the adhesive.

Failing to prep the surface properly can result in:

- Weak bond strength

- Poor conductivity

- Early bond failure during thermal or mechanical stress

Cohesive vs. Adhesive Failure (Yes, Like an Oreo®)

A simple way to evaluate bond quality is by looking at how a bond fails.

- Cohesive failure occurs when the epoxy splits within itself, leaving adhesive on both surfaces—this is ideal and shows a strong bond to the substrate.

- Adhesive failure happens when the adhesive peels cleanly from one surface, suggesting poor adhesion due to contamination or inadequate prep.

Think of it like an Oreo®: if the cream splits evenly on both sides, that’s cohesive failure. If all the filling sticks to one cookie, that’s adhesive failure.

Types of Bonding: Mechanical vs. Chemical

Bonding isn’t just about “stickiness.” Epoxies bond through two mechanisms:

- Mechanical bonding: Adhesive grips into microscopic crevices on the surface—like molecular Velcro®.

- Chemical bonding: True molecular interaction between the adhesive and substrate surface.

Both types of bonding are vital. That’s why surface roughening and chemical treatment are often necessary steps.

Methods for Increasing Surface Adhesion

Optimal surface preparation typically includes two main steps:

1 – Cleaning (Solvent + Abrasion)

a) Solvent Cleaning

Use a clean cloth with a solvent such as acetone or isopropyl alcohol (IPA) to remove oils, dust, and organic contamination. Allow to dry completely.

b) Abrasive Cleaning

Grit blasting, sanding, or detergent scrubs remove oxides and roughen the surface for better mechanical bonding. Follow with a solvent wipe for best results.

2 – Chemical Treatment

After mechanical cleaning, chemical treatments further enhance surface activity. These typically involve etching compounds like acids or reactive solvents that change the surface chemistry, making it more receptive to bonding.

Always follow proper chemical safety protocols and consult the SDS before using etchants.

Surface Prep Guide by Substrate

This chart offers a general overview of how to prepare different substrate types:

| Substrate | Cleaning & Abrasion | Chemical Treatment | Notes |

| Aluminum & Alloys | Vapor degrease, detergent scrub | Acid etch with H₂SO₄ & CrO₃ | Etch at 150–160°F for 12–15 mins |

| Copper & Alloys | Wipe with chlorinated solvent, abrade with emery paper | FeCl₃ solution, HNO₃ | Rinse thoroughly and dry |

| Gold, Platinum, Silver | Vapor degrease, abrade with emery paper for silver only | None | Abrade and clean only |

| Nickel | Vapor degrease, abrade with emery paper | Conc. HNO₃ | Dip for 5 sec, rinse |

| Stainless Steel | Vapor degrease, abrade with alumina grit paper | Cr₂O₃ in H₂SO₄ | Rinse and dry thoroughly |

| Plastics (PC, PTFE, PP, etc.) | Degrease with MEK or acetone, abrade with emery paper | Use chromic acid or Na-naphthol/THF for fluorocarbons only | Rinse and dry thoroughly |

| Glass / Optical Glass | Vapor degrease with MEK or Ultrasonic bath | CrO₃ + DI water for non-optical only | Rinse and dry < 100°F |

| Ceramics | Vapor degrease with MEK, abrade with emery paper | None | Abrade and dry only |

Final Thoughts

Surface preparation isn’t just a nice-to-have—it’s essential to the success of your adhesive bond. Whether you’re working in electronics, optics, aerospace, or general manufacturing, proper cleaning and chemical prep can:

- Improve bond strength

- Increase product reliability

- Reduce failure rates

- Ensure repeatable, high-quality results

Our technical team is here to support you with recommendations tailored to your materials, adhesives, and application requirements.

Email us at techserv@epotek.com.