Getting epoxy dispensing right can mean the difference between a strong, reliable bond and a costly failure. Whether you’re working in electronics, aerospace, medical devices, or general assembly, the secret to consistency lies in selecting the right dispensing components. Skip the trial and error—here’s your streamlined guide to precision.

Why Component Selection Matters

Whether you’re dispensing microdots or ribbons of adhesive, the right components minimize waste, improve accuracy, and protect against common problems such as voids, air bubbles, and inconsistent flow.

Let’s break down the key elements to consider:

Choose Your Barrel for the Job:

-

Clear Barrels – your all-purpose choice, perfect for monitoring fluid levels with most epoxies.

-

Amber Barrels – block UV light, protecting light-sensitive or UV-curable adhesives.

-

Black Barrels – offer complete light blockage for the most sensitive formulas.

Tip: Never fill a syringe more than two-thirds full. This air gap is crucial for maintaining consistent pressure from the first drop to the last.

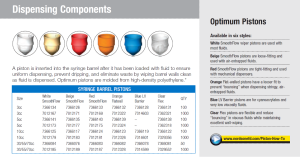

Selecting the Ideal Piston

When it comes to pistons, you have six specialized options:

-

White: General-purpose use with most epoxies

-

Beige: For aerated or air-entrapped mixes

-

Red: Essential for mechanical or automated dispensers

-

Orange: Reduces bounce in stringy, viscous epoxies

-

Blue: Best for very low-viscosity fluids like cyanoacrylates

-

Clear Flex: Ideal for filled or abrasive systems

Match the Piston to Your Material: Don’t just grab any piston. Different styles manage viscosity and air differently. The right choice prevents bouncing, ensures a good seal, and delivers consistent pressure. For example, flexible pistons are ideal for filled systems, while low-viscosity barrier pistons stop drips with runny materials.

Choosing the Right Tip

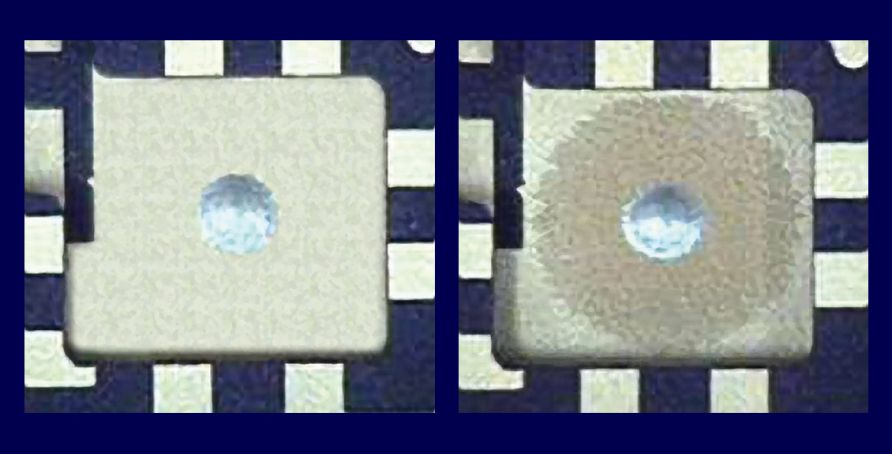

The dispensing tip is where your process meets the product. It directly controls deposit size, shape, and quality.

Select the Right Style:

-

Tapered Tips: The go-to for filled epoxies. Their design reduces required pressure and minimizes clogging.

-

Straight Wall Tips: Offer precision for general micro-dispensing applications.

-

Ceramic Tips: Essential for micro-dots and highly abrasive pastes, offering exceptional wear resistance.

-

Oval Tips: Create perfect flat ribbons for sealing or beading applications.

-

Flexible/Angled Tips: Safely reach into recessed areas or around delicate components without scratching.

Remember These Two Rules:

-

The Dot Size Rule: Your dispensed dot diameter will be approximately 2.5 times the tip’s inner diameter.

-

The Clog Prevention Rule (for filled epoxies): The tip’s inner diameter should be at least 5 times larger than the maximum particle size in your material.

See the full color-coded tip size chart for gauge, inner, and outer diameters of all standard tips.

All-in-One Cartridge Solutions

For applications requiring no measuring, no hand-mixing, and consistent ratios every time, pre-loaded dual-chamber cartridges offer a streamlined alternative. Systems like TriggerBond cartridges (available in 50ml to 400ml sizes) deliver a virtually air-free, perfectly mixed epoxy directly from the gun to your substrate.

When to choose cartridges:

-

Small to medium bonding, sealing, or potting jobs

-

When repeatability and ratio accuracy are critical

-

To reduce waste and minimize operator contact with chemicals

-

For fast-curing systems where mixing time matters

Best practice: Always discard the first shot to ensure proper mixing and replace the static mixer during pauses with fast-cure formulas.

Quick Troubleshooting Guide

Even with the right setup, issues can occur. Use this quick-reference table to diagnose common problems.

| Problem | Likely Cause | Quick Fix |

|---|---|---|

| Inconsistent Dots | 1. Worn or damaged tip

2. Piston mismatch (e.g., using a white piston for a viscous, filled epoxy) 3. Unstable dispensing pressure |

1. Replace the dispensing tip.

2. Match piston to viscosity: Clear Flex for high viscosity/filled systems; Orange for stringy materials. 3. Use the lowest stable pressure; ensure the syringe is ≤ ⅔ full. |

| Frequent Clogging | 1. Tip inner diameter (ID) too small for filler particle size

2. Fast-cure epoxy starting to gel in tip |

1. Ensure Tip ID ≥ 5 × Max Particle Size.

2. Use larger tips, shorten pause times, or purge/clean tips regularly. |

| Bubbles in Deposit | 1. Air entrapped during mixing or loading

2. Oval tip creating uneven flow |

1. Use a loose-fitting piston (Beige or Orange).

2. Switch to a tapered tip. |

| Dripping or Stringing | Epoxy viscosity too low | Use a Blue LV Barrier piston. |

| Piston Bouncing/Sticking | Stringy or highly viscous epoxy | Switch to an Orange Flat-walled or Clear Flex piston. |

| Epoxy Curing in Barrel | UV exposure in clear barrel | Use an amber or black light-blocking barrel. |

Final Thoughts

Proper component selection is essential for achieving accurate and efficient epoxy dispensing. From the tip size to piston style and pressure settings, every choice impacts the final outcome.

Get in touch

Looking to optimize your dispensing process? Our experts can help guide you through selecting the best components for your specific application.

techserv@epotek.com