When it comes to efficient adhesive dispensing, many customers opt for premixed and frozen two-component epoxies. These materials are typically packaged in syringes and used with automated dispensing equipment, offering the convenience of pre-measured and properly mixed components. However, to get the best performance from these products, proper handling is critical. Below are essential guidelines to ensure the integrity and usability of your epoxy materials.

Why Use Premixed and Frozen Epoxies?

Premixed and frozen epoxies eliminate the manual steps of weighing and mixing two-component systems, reducing the risk of human error and ensuring consistency in formulation. These benefits make them ideal for high-precision and high-volume manufacturing processes.

Shipping and Storage

Premixed and frozen syringes are shipped in dry ice to maintain a temperature below –37°C. Once received, it is crucial to immediately transfer the syringes to a freezer capable of maintaining that same temperature to preserve material quality.

Handling Frozen Syringes: Do’s and Don’ts

Frozen syringes are sensitive to both physical handling and environmental exposure. To prevent damage and ensure optimal performance:

- Always handle syringes by the needle nose or flanges.

Avoid touching the barrel directly, especially without gloves. Doing so can cause the epoxy to separate from the syringe wall, introducing freeze-thaw voids and air or moisture contamination. - Wear insulating gloves when necessary to facilitate safe handling.

- Never place syringes on their sides while thawing—this can lead to uneven thawing and air entrapment.

Thawing Guidelines

Proper thawing is key to maintaining material performance. Follow these steps:

- Place the syringe vertically in a test tube rack or similar support with the flange end up and needle end down.

- Thaw at room temperature using the chart below as a guideline:

Syringe Size Thaw Time 1–3 cc 15 min 5 cc 30 min 10 cc 40–60 min - Wait until the epoxy is fully thawed before dispensing. If the material appears too viscous, allow additional time to reach optimal flow.

- Remove the end cap first, followed by the tip or luer lock cap, to prevent material loss from pressure buildup.

Understanding Pot Life

The pot life of your epoxy starts once thawing begins. Although it is generally consistent with the pot life listed on the product’s datasheet, note:

- Thawing time reduces available working time.

- Additional handling during syringe packaging may also shorten pot life.

- To avoid compromising bond performance, err on the side of caution and do not dispense material close to the end of its pot life window.

Do Not Refreeze

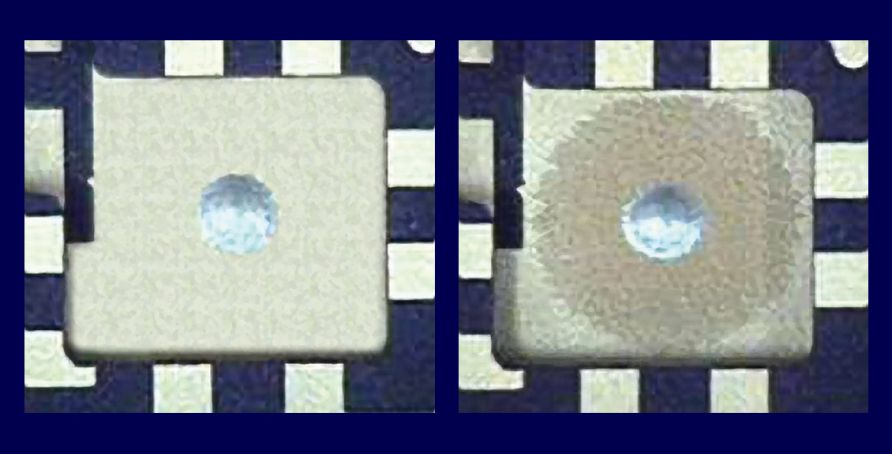

Refreezing used syringes is strongly discouraged. It can trap moisture inside the syringe, causing:

- Freeze-thaw voids

- Cure inhibition

- Reduced bonding performance

To avoid waste, order only what you need—for example, request 1 cc of material in a 3 cc syringe if that’s your daily usage.

Optional: Use a Stepped Thawing Process

For sensitive applications, a stepped thaw process may help reduce Freeze-Thaw Voids (FTV):

- Move the syringe from –40°C to a standard freezer (0°C) for 30–60 minutes.

- Then allow the syringe to thaw at room temperature.

This gradual temperature change helps compensate for potential differences in the coefficient of thermal expansion (CTE) between the syringe barrel, plunger, and epoxy, reducing the chance of cracking or voids.

Final Tip: Handle with Care

Remember, frozen syringes can be brittle and prone to cracking. Always handle with care, and use proper thawing and dispensing techniques to maintain adhesive performance and avoid costly issues during production.

Need help optimizing your adhesive processes?

Our team is here to assist with product selection, process support, and custom packaging solutions tailored to your needs. Contact us today at techserv@epotek.com.