When working with epoxies that cure at room temperature, you may occasionally notice a surface that feels sticky, looks cloudy, or lacks the smooth, glassy finish typical of a properly cured sample. These imperfections are often the result of a chemical side reaction known in materials science as amine blush — a phenomenon that can compromise both the appearance and performance of your cured epoxy.

In this post, we’ll explore what amine blush is, why it occurs, and how to prevent it, especially in applications that require high-quality finishes or critical functional properties.

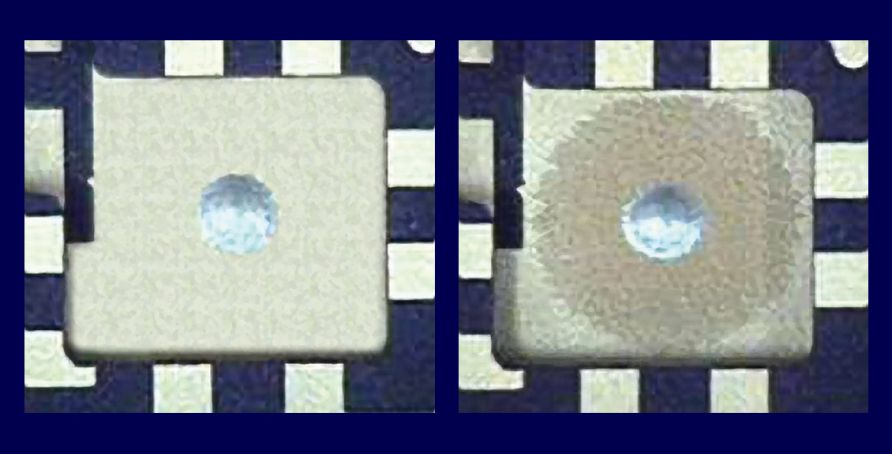

Amine blush refers to the sticky, oily, or waxy residue that sometimes appears on the surface of ambient-cured epoxy resins. It’s most commonly observed as:

- Greasy white spots

- Salt-like or crystalline deposits

- Cloudy, milky, or gray discoloration

- General surface tackiness or dullness

These surface defects are not just cosmetic — they can interfere with adhesion in secondary processing steps like painting, coating, or bonding, and may impact performance in sensitive applications.

Blush vs. Bloom: What’s the Difference?

While often used interchangeably, amine blush and amine bloom refer to two different mechanisms:

- Amine blush results from moisture condensing on the epoxy surface, reacting with the curing agent.

- Amine bloom, on the other hand, is caused by water-soluble compounds migrating to the surface, leaving sticky patches or watermark-like deposits.

Both result in similar surface issues, but understanding the root cause helps tailor the prevention method more precisely.

Why Does Amine Blush Happen?

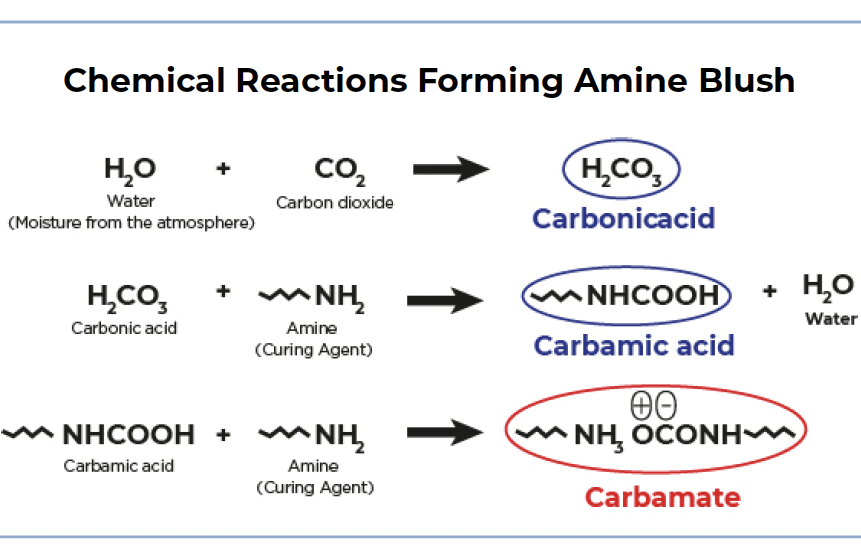

Epoxy systems that use amine curing agents are particularly susceptible to blush because amines are hygroscopic — they attract and absorb moisture from the air.

In ambient conditions, this moisture reacts with the curing amines to form ammonium carbamate by-products, leading to the surface contamination observed as blush or bloom. The risk increases with:

- Longer pot life amines, which remain reactive for extended periods before gelling.

- Low exothermic reactions, particularly in small-mass cures that don’t generate enough heat to drive proper polymerization.

Where is Amine Blush Commonly Found?

Applications that frequently rely on room temperature epoxy curing are especially vulnerable. These include:

- Medical implant molding

- Medical device coatings

- White reflector coatings for X-ray scintillator crystals

- LED array potting

- PCB encapsulation (large-scale)

In these settings, the consequences of amine blush can be more than aesthetic — potentially affecting device performance, safety, or compliance.

7 Practical Ways to Prevent Amine Blush and Bloom

Avoiding amine blush starts with minimizing the epoxy’s exposure to ambient moisture during curing. Here are tried-and-true techniques:

-

Avoid Open Benchtop Curing

Even at the same temperature (e.g., 23°C), epoxy cures better in an oven than exposed to lab air. Enclosed environments reduce moisture exposure.

-

Use a Closed Curing System

Cure parts inside a sealed container, desiccator, nitrogen dry box, fume hood, or under a glass bell jar to prevent ambient humidity from interfering with the reaction.

-

Stabilize Temperature & Humidity

Slight increases in cure temperature can make a big difference. For example, 28°C is preferable to 25°C; 23°C is better than 21°C. Seasonal shifts in humidity and temperature can have surprising impacts.

-

Always Cure Above the Dew Point

Curing below or near the dew point encourages condensation — a major trigger for blush. A common practice is to cure at +3°C above the dew point. Where this isn’t feasible, use fans or heat lamps to prevent moisture from settling.

-

Watch for Small-Mass Curing

Tiny amounts of epoxy (<1g) don’t generate much exotherm and are more vulnerable to blush. Mix larger batches than needed and divide them as required for curing.

-

Fuel the Exotherm

Allow your mixed epoxy to sit in a container and advance toward gel stage before applying. This helps promote favorable amine-epoxide reactions over undesirable amine-moisture ones. The shorter the pot life, the quicker the gel, and the more effective this technique.

-

Use Extra Potting Thickness

Surface layers are more prone to blush, while deeper sections often cure cleanly. Try over-potting or over-encapsulating by an extra few millimeters, then mechanically remove the top layer by milling, cutting, or dicing.

Conclusion: Manage Humidity, Improve Results

When working with room-temperature curing epoxy systems, moisture control is critical. Whether you’re in R&D, manufacturing, or quality assurance, understanding and preventing amine blush ensures better surface finishes, more reliable performance, and fewer downstream issues.

By implementing the preventive strategies above, you can safeguard your materials from the effects of amine blush or bloom — and maintain the integrity your applications demand.

Get in touch

Still unsure or need help setting up a test? We’re always here to support your technical questions.

Call us at 978-667-3805 or email us at techserv@epotek.com.