When working with two-component epoxy systems, ensuring the correct mix ratio is critical to achieving a proper cure. However, not all processes are designed for weight-based measurements—which is why understanding how to convert from mix ratio by weight to mix ratio by volume is essential.

In this guide, we’ll explain the importance of mix ratios, where to find them, and how to accurately convert them using real-world examples.

What Is a Mix Ratio?

A mix ratio is the proportion in which the resin (Part A) and hardener (Part B) of a two-part epoxy must be combined to trigger a full chemical cure. This ratio is product-specific and is typically defined by the stoichiometric balance—the point at which all reactive groups in the epoxy components are properly matched.

Mix ratios can be expressed by weight, by volume, or as PHR (part per hundred resin). Due to differences in density between resins and hardeners, the weight ratio and volume ratio will often differ. For example, a 1:1 mix ratio by volume might correspond to a 100:83 ratio by weight, depending on specific gravities of the components.

Why Accurate Mixing Matters

Even small errors in the mix ratio—more than ±5%—can result in:

- Incomplete curing

- Higher levels of outgassing

- Lower glass transition temperature (Tg)

- Reduced chemical and moisture resistance

- Soft cure, high exotherm leading to shrinkage during the reaction.

That’s why accurate measurement and proper conversion between weight and volume are vital for performance and reliability.

Where to Find Mix Ratios

Epoxy Technology lists all mix ratios by weight in the TDS for each two-part product. But in practical settings, especially where tools or processes are optimized for volume, you may need to convert the weight-based ratio to a volumetric one.

Important: Using a weight-based ratio for volumetric mixing without conversion can lead to curing issues.

How to Convert Mix Ratio by Weight to Volume

To convert, you’ll need:

- The weight-based mix ratio

- The specific gravity (SG) of each component (found on the TDS)

Formula:

Let’s look at two real examples to illustrate the process:

Example 1: EPO-TEK® 353ND

- Mix ratio by weight: 10:1

- Specific Gravity: Part A = 1.20, Part B = 1.02

Step 1: Convert each part to volume

- Part A: 10g ÷ 1.20 = 8.33cc

- Part B: 1g ÷ 1.02 = 0.98cc

Step 2: Normalize volume ratio

- 100 : b format → 0.98 ÷ 8.33 × 100 = 11.8

- a : 1 format → 8.33 ÷ 0.98 = 8.5

Volumetric Mix Ratio (a:1): 8.5 : 1

Example 2: EPO-TEK® H20E

- Mix ratio by weight: 1:1

- Specific Gravity: Part A = 2.03, Part B = 3.07

Step 1: Convert each part to volume

- Part A: 1g ÷ 2.03 = 0.493cc

- Part B: 1g ÷ 3.07 = 0.326cc

Step 2: Normalize volume ratio

- 100 : b format → 0.326 ÷ 0.493 × 100 = 66.1

- a : 1 format → 0.493 ÷ 0.326 = 1.51

Volumetric Mix Ratio (a:1): 1.51 : 1

Other Common Ratio Expressions: PHR

Some technical data sheets express ratios as PHR (parts per hundred resin). This is a weight-based ratio where the resin represents 100 parts, and the hardener is expressed relative to it.

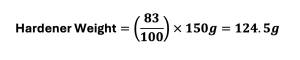

Example: If a product has an 83 PHR ratio and you measure 150g of resin:

Final Tips for Accurate Mixing

- Always refer to the Technical Data Sheet for mix ratios and specific gravities

- Avoid estimating or using weight ratios for volumetric mixing without conversion

- For filled systems, always remix both resin and hardener in their original containers before measuring to prevent filler settlement.

- Use precise digital scales and graduated cylinders for best results

- Document your conversions for repeat batches to ensure consistency.

- When in doubt, consult with your supplier’s technical team

Need help converting ratios for your epoxy system? Reach out to us at techserv@epotek.com.