Features

- Non-Corrosive, Electronic Grade

- Heat & Cold Resistant

- Excellent Electrical Properties

- Long-Lasting Durability

- Resistant To Some Chemicals

- Good Stress Relieving Properties

- Excellent For Bonding, Sealing, or Encapsulating

- Advanced Adhesion To Various Substrates

Benefits

- 100% Silicone

- Broad Adhesion Range/Bonds to Common Substrates

- Chemical Resistant

- Color Stable

- Compatible with Electronics

- Excellent for Encapsulating/Sealing/Coating

- High Temperature Resistance

- Highly Flexibile/Allows for Movement

- Long Life

- Low Odor

- Low Temperature Resistance

- Moisture Curing

- Mold and Mildew Resistant

- Non-Melting

- Non-Slump – Overhead/Vertical Applications

- Non-Yellowing

- One-Component

- RTV

- Self-Leveling

- Solvent-Free

- UV Resistant/Degredation

- VOC Compliant

- Water Repellant

- Weather Resistant

- Will Not Crack

- Withstands Extreme Temperatures

Properties

- *Intermittent temperature up to 450°F. Strength will start to develop immediately and continue increasing for 7 days after application. ASI recommends testing strength and adhesion on the 7th day. ASI 388 suggested application temperature range: -35°F to 150°F. Testing should be done to confirm temperature requirements are met. Information on this data sheet can change without notice and it is therefore not recommended that these figures be used in spec writing. If you have any questions contact manufacturer‘s sales and technical service department.

Substrates

- Glass

- Most Metals

- Most Fiberglass

- Most Wood Types

- Aluminum

- Porous Surfaces

- Vinyl

- Rubber

- Natural & Synthetic Fiber

- Most Painted Surfaces

- Some Plastics

Downloads

Certifications

- UL Recognized

- VOC Compliant (21 grams/liter ASTM D2369)

- Meets the requirements of MIL 46106B Type 1

Additional information

ADDITIONAL COMMON APPLICATIONS

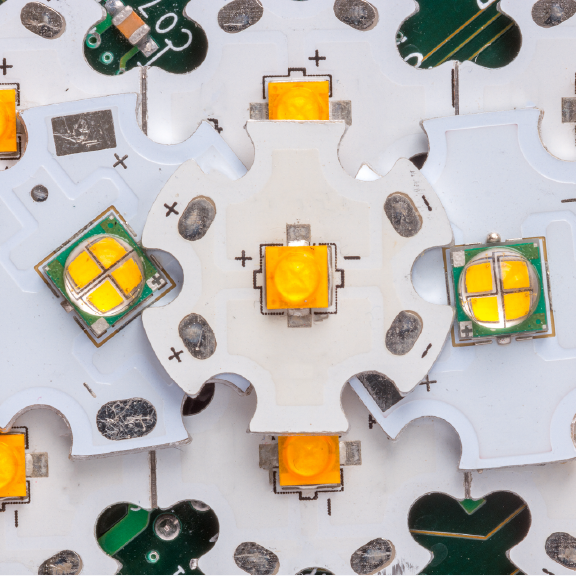

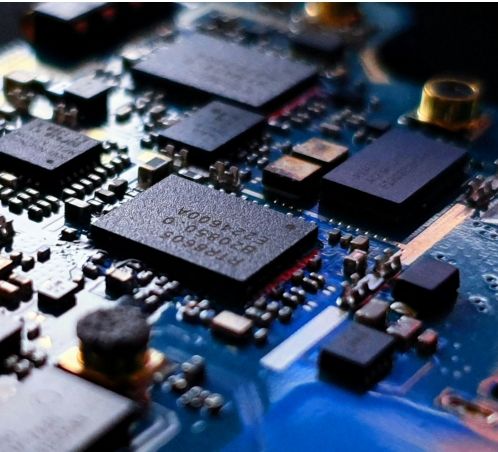

- Sealing Lead Wire Entries

- Waterproofing Electronics

- Component Mounting

- Covering Sensitive Components

- Sealing Electronic Assemblies

- Adhering Electronics

- Sealing/Bonding Electronics

- Circuit Board Protection

- Electronic Encapsulating

- Electrical Connections

- Telecommunications Including Coaxial Cable Connectors, Etc.

- Engine Components

- General Industrial Applications

Available Packaging

Notes

ASI 388 is stocked in cartridges, 2.8 oz. squeeze tubes, pails and drums. Additional packaging may be available upon request. Inquire to ASI sales staff for additional information.

Related Products

Hot Melt Adhesives

Evans Adhesive's hot melt adhesives provide fast-setting, durable bonds for packaging and converting industries, offering reliable performance, efficient application, and strong adhesion to meet the demands of high-volume production environments.

60-7107RTR

Electronic Epoxy Adhesive

Electronic grade epoxy UV adhesive, coating, and encapsulant with a CTE of 35 ppm/C.

EPO-TEK® EK1000

Electrically Conductive Silver Filled Adhesive

High thermal conductive silver filled adhesive.

ASI 504

Multi Purpose RTV Silicone Sealant and Adhesive

ASI 504 Multi-Purpose Silicone can be used as both a sealant and adhesive for a variety of applications requiring a waterproof seal. It Is a paste-like, one component acetoxy silicone that cures to form a durable solid rubber...

ASI 57

Hybrid Polymer Sealant and Adhesive

ASI 57 Hybrid Class 50 Hybrid Sealant and Adhesive is a one-part, low odor, no-sag polyether sealant that uses ASI’s innovative hybrid technology to produce a material that is ideal for a wide range of applications where a...

10-2080

Polyurethane Adhesive

10-2080 is a general purpose, semi rigid polyurethane adhesive for bonding a wide variety of plastic and metal substrates. Its flexibility allows bonding to substrates with high coefficients of thermal expansion.

Hot Melt Adhesives

Evans Adhesive's hot melt adhesives provide fast-setting, durable bonds for packaging and converting industries, offering reliable performance, efficient application, and strong adhesion to meet the demands of high-volume production environments.

60-7107RTR

Electronic Epoxy Adhesive

Electronic grade epoxy UV adhesive, coating, and encapsulant with a CTE of 35 ppm/C.

EPO-TEK® EK1000

Electrically Conductive Silver Filled Adhesive

High thermal conductive silver filled adhesive.

ASI 504

Multi Purpose RTV Silicone Sealant and Adhesive

ASI 504 Multi-Purpose Silicone can be used as both a sealant and adhesive for a variety of applications requiring a waterproof seal. It Is a paste-like, one component acetoxy silicone that cures to form a durable solid rubber...

ASI 57

Hybrid Polymer Sealant and Adhesive

ASI 57 Hybrid Class 50 Hybrid Sealant and Adhesive is a one-part, low odor, no-sag polyether sealant that uses ASI’s innovative hybrid technology to produce a material that is ideal for a wide range of applications where a...

10-2080

Polyurethane Adhesive

10-2080 is a general purpose, semi rigid polyurethane adhesive for bonding a wide variety of plastic and metal substrates. Its flexibility allows bonding to substrates with high coefficients of thermal expansion.

Get in touch to learn more

Speak to us on 800-325-7040

Contact us

Technical Data Sheet

Technical Data Sheet